The 4 production steps

The way to the finished noodle

Step 1

-

The durum wheat semolina is transported from the external silos to the production facilities.

-

Fresh quality class A eggs from German barn management are processed immediately, which guarantees absolute safety and quality.

-

The raw materials - durum wheat semolina, fresh eggs and water - are fed via the dosing systems into the dough mixer, following the respective recipe.

-

Careful mixing of the dough is essential.

Step 2

-

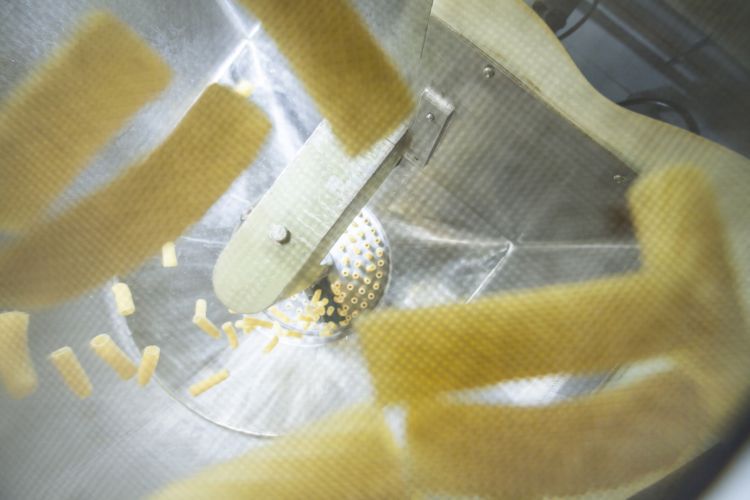

Spätzle

The dough is pressed through perforated plates and then drops into a cooking bath. Here, the Spätzle are briefly pre-cooked and thus retain their shape.

-

Rolled noodles

The dough for the rolled noodles goes through several rolling processes and is then cut to the desired width.

-

Pressed noodles

The dough is extruded through the die in the press at a pressure of approx. 100 bar.

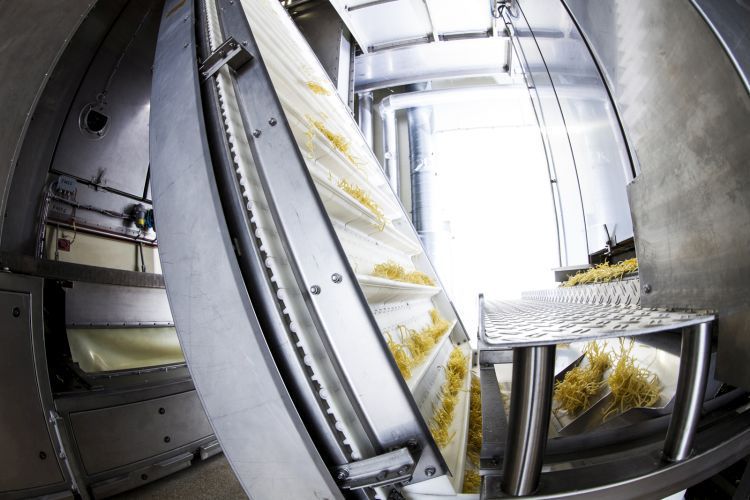

Step 3

-

The formed noodles pass through three drying steps during which the moisture is evenly extracted from the inside to the outside.

-

In the long drying lines, the water content is reduced from over 30 % to a maximum of 13 %.

-

The slow and gentle drying process preserves the nutrients in the pasta.

-

Despite modern technology, continuous monitoring by our trained specialist staff is essential.

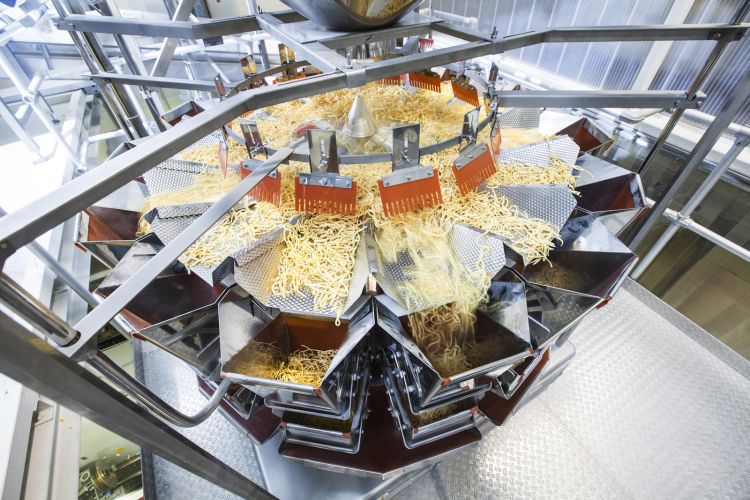

Step 4

-

From the scales it goes via the fully automatic bag filling machine into the shipping carton.

-

We offer customer-specific packaging in various sizes, 500 g for the retail trade, 2.5 kg for the catering trade, 10 kg for commercial kitchens and 500 kg BigBags for industrial customers.

-

Our order processing ensures fast delivery.

-

Our warehouse with perfect logistics prevents bottlenecks.